We are going back in time again to catch up on progress with the UniMog and bring us a little more up to date. It was going to take a lot of work to convert an old fire engine into a capable and comfortable overland vehicle. The basics were being done by South Cave Tractors in Hull whilst we returned to Africa in February 2024 for the last leg of our African adventure.

In the seven months we were away they ensured that the truck was ready to start the conversion, including having to replace all the brakes, discs and calipers after it failed the first MOT. We also discovered through the MOT that the tyres were out of date so had to arrange for five new ones to be shipped to South Cave to be fitted.

It passed the second MOT but a few weeks later we were told that the original fuel tank was contaminated with a bacteria known as diesel bug which cannot be removed so we had to buy a new one of those as well.

All this, and the surprisingly high cost of re-registering the UniMog as a 7.5 tonne vehicle, put us significantly over our already strained budget and we had barely got started.

As we travelled through east Africa, South Cave ploughed away with their work and sent us regular updates and photographs.

The new fuels tanks went in

The new grill and bonnet were fitted

And the new tyres went on

Our previously well-kept UniMog spent a worrying amount of time in their yard, out in the open for the first time in his life, subjected to the wind and rain

But we tried not to worry, he was made of stern stuff and surely it would take more than seven months for him to start rusting?

In the meantime, we needed to source the habitation box. We contacted the German UniMog specialists that we had visited over Christmas. They had quoted us €25,000 plus tax to design and build an empty box. Windows and doors would be an extra €11,000.

It was a high cost but weeks and weeks of searching had not found any other reliable manufacturer who could do it any cheaper. They had also advised us that it would take five months to complete the build from when we placed the order and we planned to collect it in July. So at the beginning of February we made the decision and asked them to place the order.

The next day they replied with an invoice and an order form to complete. The invoice was for €40,000 plus tax plus windows and doors. If I hadn´t had my seatbelt on when I opened the email I would have fallen off my chair!

I asked them why the huge price increase. They came up with a few excuses which were clearly nonsense and in the end they simply said that their suppliers had increased their costs. There was to be no negotiation. We went into a tail spin – we simply could not afford it.

Six weeks went by with James spending every spare moment scouring the globe for manufacturers of habitation boxes – even contacting suppliers of refrigeration boxes as well as looking into building our own. But every way we turned was a dead end – people wouldn´t reply, quality was not what we needed or they were too expensive.

Eventually we gave in and went back to the German supplier, reducing the specifications of our box and asking to place the order. They said they would confirm next steps shortly.

We never heard from them again.

By the time we were in Uganda watching gorillas, we had finally found two manufacturers who could help us. One in China and another in Canada.

The one in China gave us a remarkably cheap quote and were able to build the box to our exact specifications and from the materials we wanted. The only problem was one of communication – they were slow to respond, not always clear in their answers and told us that we would not be able to approve any final designs prior to manufacture. We had concerns that the box could very well arrive and be completely wrong.

The supplier in Canada was entirely different. Communication was fantastic – despite the nine hour time difference he emailed us and text us multiple times a day and even organised a video call so that he could show us around his workshop. He looked at our subframe designs and pointed out problems that would make mounting the box difficult. The level of detail he was going into was giving us a lot of confidence

But the materials he was using were not what we wanted. We had already ordered the windows and doors from Holland assuming 60mm thick walls, his materials were 80mm thick so the windows and doors would not fit. And the materials appeared at first to provide a lower level of insulation and performance.

And to add to it all, his price was more than double that of the Chinese manufacturer!

After a great deal of research we discovered that the materials the Canadian manufacturer was proposing were in fact much better than what we had originally wanted. The fibreglass reinforced plastic skins were almost indestructible, the foam inside more stable and durable and the extra thickness allowed for better insulation not worse. It was actually the next generation

We contacted the window and door supplier to ask about changing from a 60mm thick box to an 80mm thick box and they said it would be fine, they hadn´t started manufacturing the windows yet – as soon as we were ready to make the decision we should let them know and they would change the specification so the windows would fit.

Things had got very confusing.

On the one hand we could wipe £15,000 off our ever-increasing costs and get a box from China that could be exactly what we wanted. Or it could be completely wrong and we would have thrown a lot of time and money down the drain.

On the other hand we had a manufacturer offering a superior product who inspired much more confidence, offered us complete control over the design with approval rights every step of the way and was actively helping us to solve problems – many of which we hadn´t even known we had. But at a huge cost.

Every day we woke up with a different opinion. One day it was China the next day Canada, the next day China again. It was exhausting.

Eventually I got up one morning and told James that I had made an executive decision – we were going with Canada. I said I would rather spend the extra money for certainty and peace of mind. He smiled at me and gave me a big hug. ´Thank you for making that decision´ he said, ´I don´t think I could have done it´.

As we waited in Uganda for our gorilla permits, we gave our Canadian manufacturer, Off Grid Customs, the good news and paid him a 75% non-refundable deposit to start work.

We were in the middle of trying to fix the design problem with the sub frame at the time and our lovely Canadian supplier was helping us. South Cave had been about to start fabricating the frame and had had to pull it from the factory at the last minute to make the changes. They desperately needed the revised drawings to get the frame back into production

Allan, the owner and our main contact at Off Grid Customs, had been working with us in real time trying to finalise the redesign. I emailed him to tell him the deposit had been paid and also sent him our proposals for how to find a compromise solution for the sub frame. I told him it was late in the evening at our end but we would wait up for his reply so we could get it over to South Cave ready for the morning.

He didn´t reply. We eventually went to bed. When we woke in the morning – the intervening time having been the whole Canadian working day – he still hadn´t replied. The next day there was still silence.

My head was reeling. Allan had not gone more than a few hours without communicating with us for the last three weeks. Now suddenly, just as we had paid him thousands of pounds and despite urgently needing his input, he had disappeared. I wracked my brain trying to work out how we had got to this point, at what stage we had been duped by a con man. Nothing made sense, he had come through a reliable source, his knowledge had been extensive, his CAD designs impressive. It all seemed far too sophisticated a con for a few thousand pounds – a huge amount of money to us but surely not enough for someone to go to this amount of effort as a scam?

On the third day Allan finally replied. No explanation, no acknowledgement that he had done anything unusual or put our sub frame design in jeopardy, just a question about some detail of the box.

It was bizarre and for the next two weeks his attitude towards us changed totally. He was offhand, unhelpful and took ages to reply to anything. Maybe this wasn´t a complete con but it seemed he was only going to be helpful and friendly until he had our money. We were disappointed.

And disappointment turned into outright anger and a level of frustration that had my brain trying to seep out of my head when Allan informed us that the cost he had quoted us did not include for some pretty basic items – like cutting the holes for the doors and windows, transporting the box to the port and various other things. He wanted an extra 30% on top to deliver what he had said he would deliver in the first place.

We were at the Source of the Nile in Uganda at this point and it may have been one of the reasons why that particular part of our trip fell a bit flat – I felt ill with worry and was struggling to concentrate on our travels with all this going on.

Eventually, after much negotiation, trying to keep things as positive as we could, we came to an agreement with him. He would cut the holes for the doors and windows manually and we would take over responsibility for the shipping. There were some other details that got ironed out and we ended up paying a little extra but certainly not 30%.

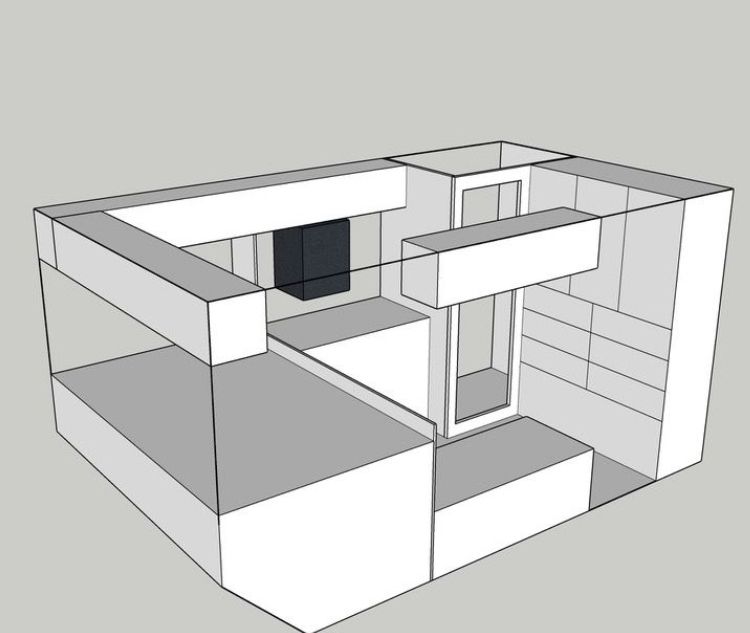

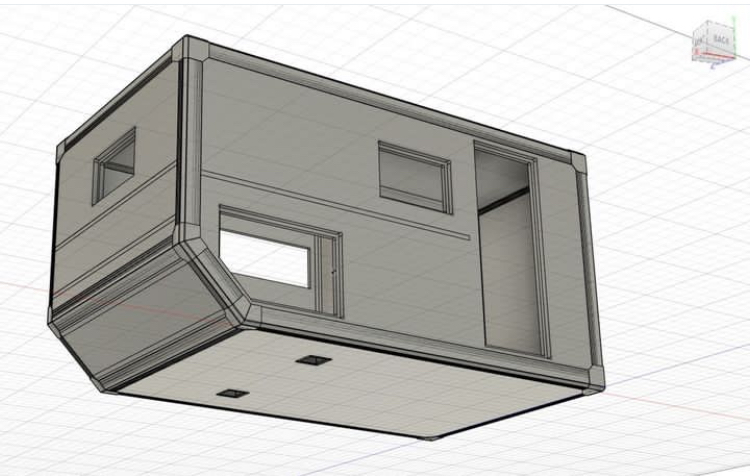

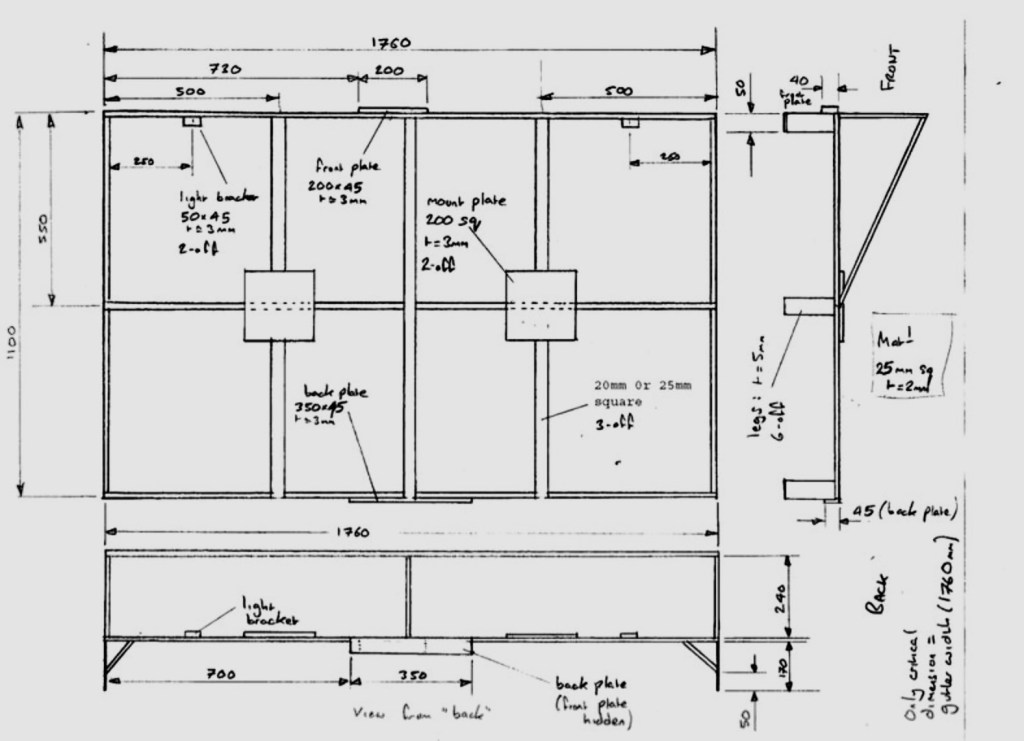

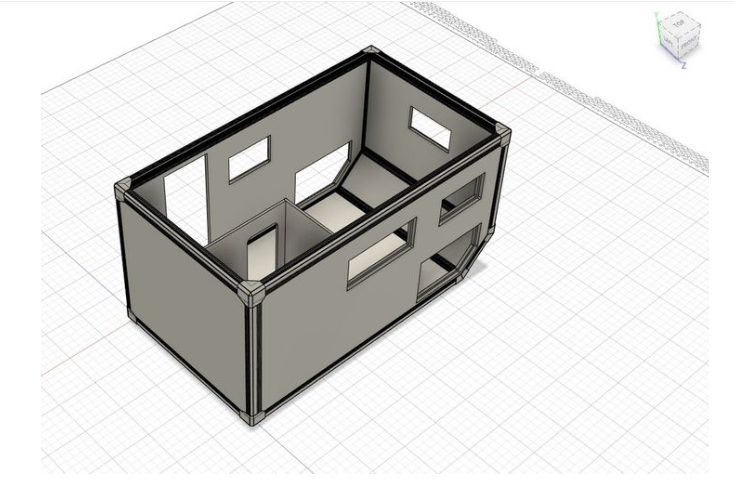

After that, things got right back on track with Allan. He became the friendly, helpful supplier we had first got to know. He pulled out all the stops to meet our timeframe and sent final 3D drawings of our box which looked amazing

Finally things had come good. Had it been a simple case of difficult communication across thousands of miles and differing time zones – probably not helped by different ways of doing things between Canada and Europe? We will never know. But whatever had gone wrong was now put right and our relationship with Allan went from strength to strength, we could not fault him.

More good news arrived, South Cave had finished the sub frame and installed it onto the UniMog´s chassis. It looked fabulous, a great bit of precision engineering

And a few days after that, construction of the box commenced. We were excited and terrified in equal measure – the cost of this box was a significant chunk of our budget and signing off the designs ready to start the build felt like a huge commitment and an even bigger leap of faith.

Allan held our hands all the way through, sending us loads of photos of the box as it progressed

The quality of the work he was doing looked exceptional

The box would be complete by the end of July. It was due to be picked up by the shipping agent on 8th August, put on a train from Vancouver to Montreal and loaded onto a ship bound for Southampton, arriving in the UK on 11th September.

So we now had a UniMog safely purchased in the UK, being looked after by trusted specialists, and a top quality habitation box under construction with shipping organised and booked. Our flights to the UK were also booked for 11th August.

Everything was finally going smoothly.

But it was not to last. By the time we arrived in the UK everything had started to go very differently from how we had planned….