Before we had even arrived in the UK the shipping dates for our Canadian habitation box had slipped. It was now being collected from Off Grid Customs on 16th August although at this stage our agent was assuring us that it would still arrive in the UK on 11th September as planned

Most of you will remember our traumatic experience of container shipping trying to get Henry from Cote D´Ivoire to Cape Town in 2022. It took 105 days to get him there instead of the promised 28 days and we had vowed never to ship anything again in our lives. I have still not quite got over it and nothing about this second attempt at international shipping was going to change my view!

We landed in the UK on 12th August and planned to spend the first week catching up with everyone and getting the car we use when we´re here back on the road. On 15th August, the day before the container was due to be collected from Off Grid Customs, our Canadian shipping agent emailed me with some bad news – there was to be a national rail strike in Canada and as such the box would not be able to get from Vancouver to Montreal in time to catch the ship.

There was nothing we could do but leave the box with the supplier, wait for the strike to be resolved and then try to re-plan.

It was a huge set-back and one which threatened to put the whole fit-out of the box in jeopardy – we had a slot booked with Lewis at Adaptvan and with him being booked up for two years in advance we could not risk any delay.

Fortunately, ships go from Montreal to Southampton at least weekly so we hoped any delay would be minor.

Our UniMog was still in Hull at South Cave Tractors and we planned to drive up and collect it sometime the following week. We had a lot of work to do on it to get it ready to put the box on and start the fit-out so we were keen to get going as soon as possible

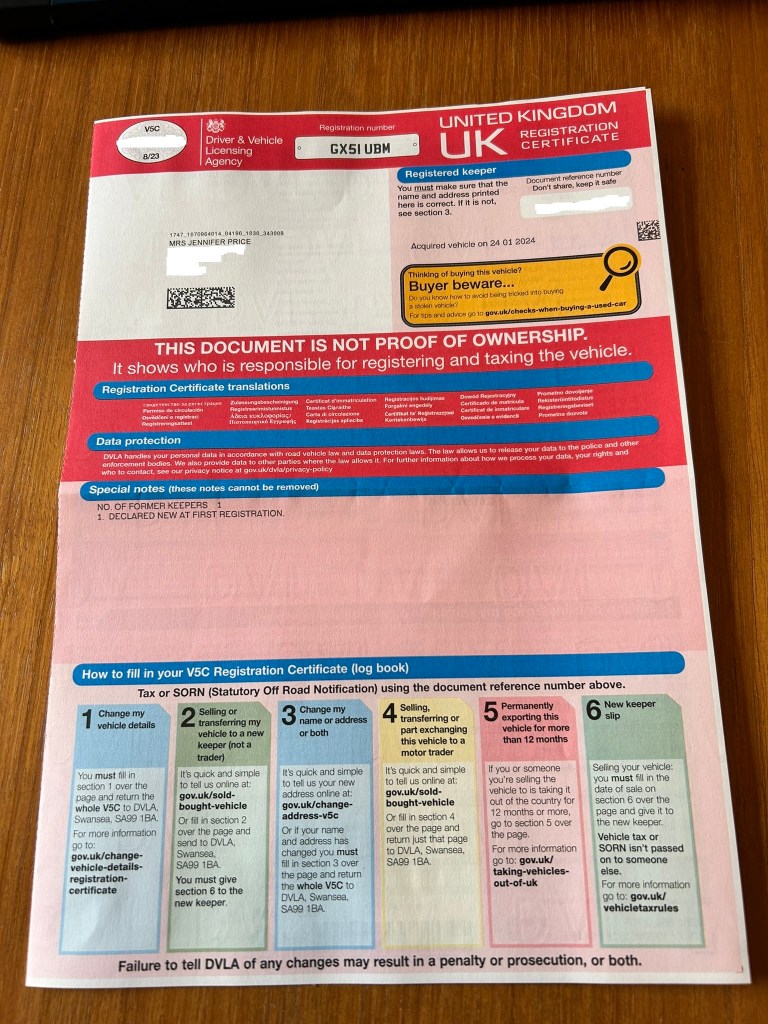

The truck was currently declared as Statutory Off Road with the DVLA so the first step was to get it back on the road and sort out road tax and insurance ready to drive it to Birmingham. We had arranged to use a barn at a farm not very far from where we used to live – the farmer was a friend of a friend and very helpful and generous.

I called him to make arrangements for our arrival. He had disturbing news. The barn had been burnt down by an arsonist the week before. Was bad luck going to follow this build everywhere we went? He wanted to help though and offered to clear the grain out of a different barn on the promise that we would be out of it before the middle of November which seemed entirely risk free at that point.

With that potential disaster averted, we agreed with South Cave that we would collect the UniMog the following Tuesday and on the Thursday before I sat down at the computer to sort out the road tax.

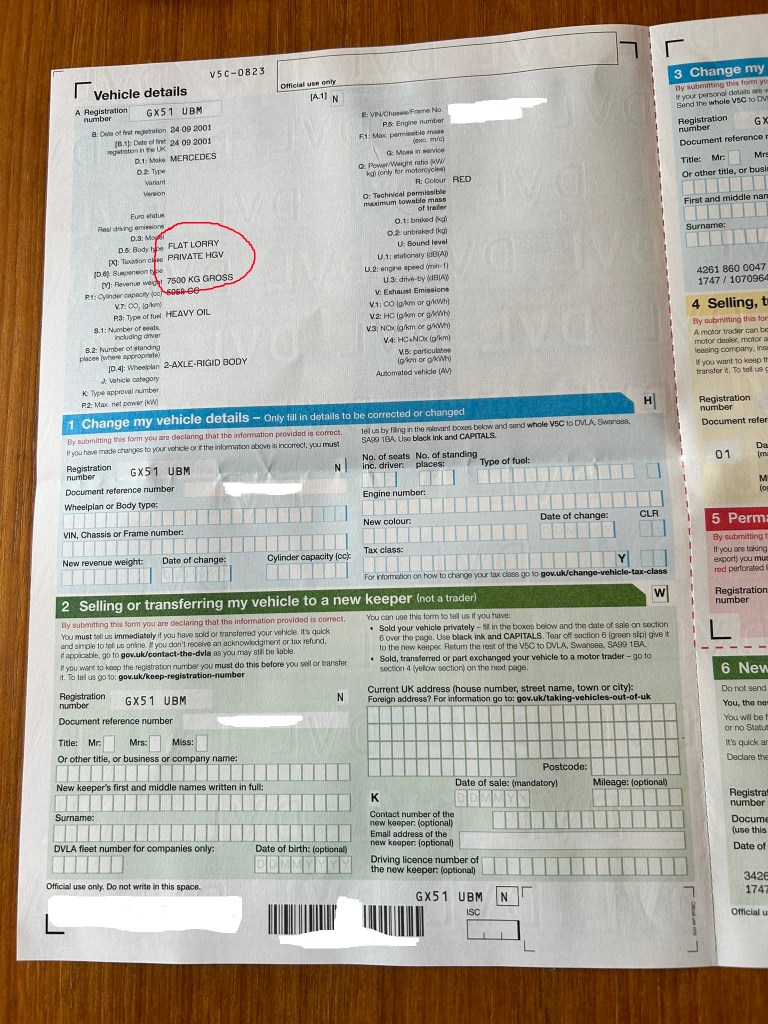

To my horror, when I put the UniMog´s details into the DVLA´s system it came up listed as a 9 tonne Fire Engine. South Cave had told us that this had all been sorted out two months ago, it was supposed to be a 7.5 tonne Private HGV.

James called them. They assured us that the DVSA (Driver and Vehicle Standards Agency) had confirmed the re-registering of the UniMog as 7.5 tonnes but that no-one had informed the DVLA (Driver and Vehicle Licensing Agency). Unfortunately they had not done anything about re-registering it as Private HGV instead of a Fire Engine.

A very long process started which I will summarise briefly, mainly because I can´t bear to re-live it! I discovered that the DVSA are the people who matter when it comes to the tonnage of a vehicle so we were ok with that, we just needed to notify the DVLA, it would not stop us driving it. But not having changed the vehicle class to Private HGV was a problem – fire engines are zero rated for road tax and can only be driven on public roads by employees of the fire service. No road tax and no employment contract as a fire girl/boy meant that we still could not legally drive it.

South Cave attempted to change the vehicle class over the counter at the Post Office only to find that it had to be done by post. The Post Office took the V5 log book from them, filled in the relevant details and posted it to the DVLA.

Not only did the DVLA website say that it was going to take up to four weeks to process the change, but when I called them to discuss our options they told me that the Post Office had done the wrong thing. In order to change the vehicle class we should have sent a cheque for the cost of the road tax along with the MOT certificate, the insurance certificate, the new tonnage certificate, the V5 log book, three separate forms and a covering letter. With the V5 having been sent on its own it would almost certainly now be lost in the process and we would need to apply for a new one with an additional fee alongside everything else.

My head was reeling. I couldn´t believe the situation we were in. Not only would a four week delay mean that we couldn´t get anything done on the UniMog to prepare it for picking up the box but we might not even be able to drive it to the port to collect the box by the time it arrived. And if we couldn´t collect the box then the port would charge us literally thousands of pounds in storage fees – they are famous for it.

But hang on, the box hadn´t left the supplier´s workshop, the rail strike was still on. I called our shipping agent and told him we had a problem. I asked him not to arrange a new shipping date until he confirmed it with me. He agreed.

At least one problem had been averted – and how ironic that the rail strike had saved us.

We were not out of the woods though, the clock was ticking and we needed to be ready to start the fit-out in time to keep our slot with Adaptvan. Plus we wanted to re-start our travels as soon as possible.

I spent the day collecting all the information we needed in order to post the package off to the DVLA without losing any more time.

Even this caused problems as trying to organise insurance on a UniMog overland vehicle that is not yet an overland vehicle and is in the process of construction is almost impossible. It took many long telephone calls to get it sorted out. But by the end of the following day the package was in the post and I needed a large glass of wine!

The four week countdown had started and we kept our fingers tightly crossed that the DVLA would pull out all the stops and get this processed far quicker.

Ten days later my package arrived back on our doorstep – returned by the DVLA with a covering letter simply saying that we had not provided sufficient information to process it.

My brain was about to burst out of my head, we were back at square one only now we were another 10 days down the line.

At this point I thought we were never going to get anywhere and decided to sell the UniMog! But things turned around surprisingly quickly.

I called the DVLA to find out exactly what I had missed – had I not sent everything they had asked me for? The helpful lady at the DVLA call centre put me through to the taxation team directly and I think my call was answered by the manager or team leader because from the moment I started talking to her everything changed.

I explained to her what had happened so far and set out the timefame for the box arriving in the UK and the consequences if we were not able to pick it up. She told me that all we were missing were some photographs of the truck so that they could decide what body type to list it as. She then told me to re-send the package addressed to her personally marked ´private and confidential´ so that their post room would not waste time opening it. She also suggested that I put my mobile number and email address in the covering letter so that she could contact me directly if any more problems arose.

The package, complete with photos, was posted back to her the same day. Two days later she called to tell me she had it and was processing the application. By the end of that day the DVLA website listed our UniMog as a 7.5 tonne Private HGV and three days after that the new V5 arrived in the post

What an absolute star and how lucky we were to have found her. Although I was a little bit sad not to own a fire engine any more.

By the time our Canadian shipping agent contacted me to offer a new shipping date we were out of the woods and could gratefully accept it. Unfortunately these problems had cost us a month and the box was not going to arrive in Southampton until 22nd October.

But at least we now had a date to work to. The box was expertly packaged up by Off Grid Customs and the shipping agent arrived as arranged to collect it and take it to Vancouver port where it would be loaded onto a train to Montreal

When Allan at Off Grid Customs sent us these photos we were equally excited that its journey had finally started and terrified about how we would get it out of the container again at the other end – it was a tight fit!

In the meantime, South Cave Tractors were also doing their best to make up for their mistake in not having sorted out the re-classification of the UniMog before we got to the UK. Going back a few weeks to when the problem was first found, we had planned to collect the UniMog from them on the Tuesday. As we could not legally drive it this was out of the window but they made us a very generous offer – one of their team drove it to us on their trade plates, delivered it to the farm in Birmingham and got a train back to Hull.

We may have been plagued with bad luck but we were also surrounded by amazing people.

So, whilst all the fuss with the DVLA was going on, our UniMog had finally made it to us

We started work on the refurbishment without any delay. Whilst we waited for the box to arrive from Canada we needed to work on the inside of the UniMog´s cab, put the new LED lights on and touch up some minor patches of rust on the chassis.

But the big ticket item that absolutely had to be done before we collected the box was to have the outside of the cab repainted. The new bonnet, grill and front wing had all been supplied unpainted and, whilst the old paintwork on the rest of it was fine, it was also uninspiring. We had spent ages trying to decide whether to simply paint it red again or choose a different colour – maybe the same grey as the box.

In the end we decided to keep the UniMog authentic to its roots and stick with the red – he may not have had his blue lights any more but he was still a fire engine at heart.

We were going to have him painted at Pegasus Bodyshop in Redditch, a company owned by James´ nephew Jonathan whose skills and quality are second to none – he even painted the James Bond cars for the films. Pegasus specialise in high end cars and have never done anything like a UniMog. James had had to go in to measure the size of their painting oven to see whether it would fit inside – it would, but only just. With the box on the back we would have no chance of fitting it in – if we going to paint it, we had to do it before the box arrived.

By the time the UniMog was at the farm we had just over six weeks before the ship from Montreal was due in at Southampton port – it seemed plenty of time. The painting was expected to take two weeks then we would need to deck the back out with plywood and finish putting the seats and upholstery into the cab. So we planned for three weeks to do the cab and rust-proofing then three weeks for the painting and finishing.

Work started in earnest. We had bought new tools for the job – supersized tools for a supersized truck

We had to drive an hour each way to the farm everyday leaving my Mum´s place between 6-7am and not getting back until 6-7pm

The cab had the old, original seats and trims, all of it dirty and ripped. There were so many cables and wires installed by the fire service that it was hard to see through them

I wondered what on earth we had got ourselves into….

James and I worked together but, of course, he did all the tricky bits, carefully removing everything from inside

Within the first day it was all gone. It was a big improvement but it was still looking shabby

But by the end of that day we had cleaned it up and it looked like a different cab

Although with the bonnet and grill also removed the poor thing was looking a bit sorry for itself

As we got into the work we started to find a few problems that needed dealing with. One of the mud guards was rusted through

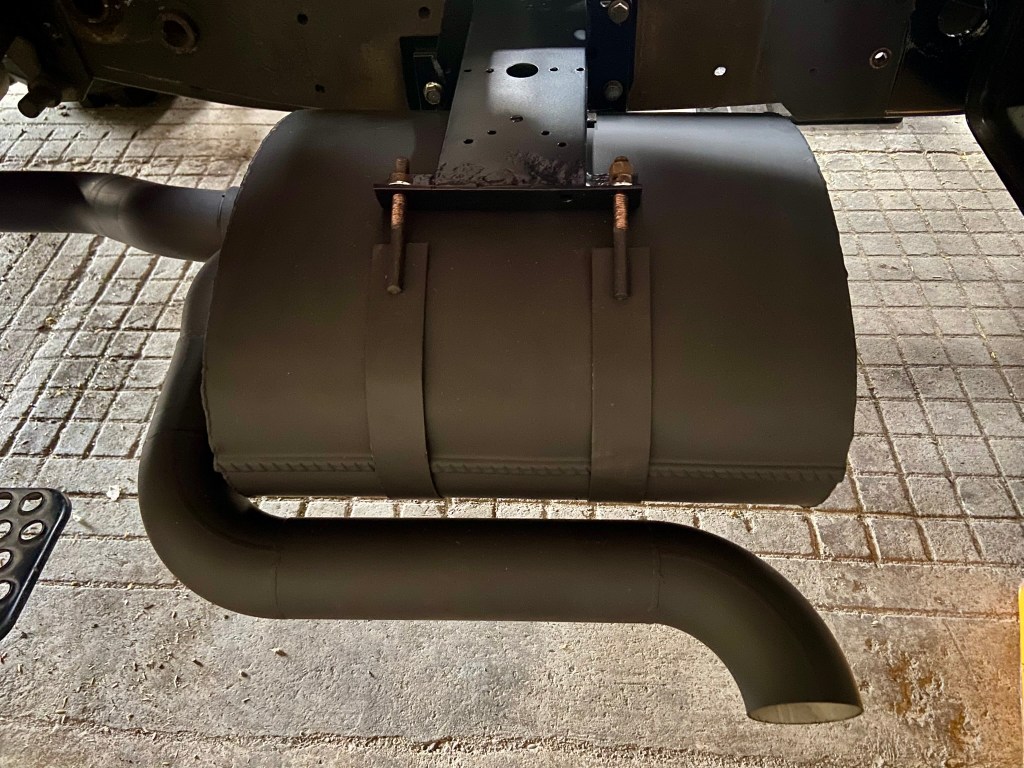

The exhaust was also very rusty and the pipe was corroded

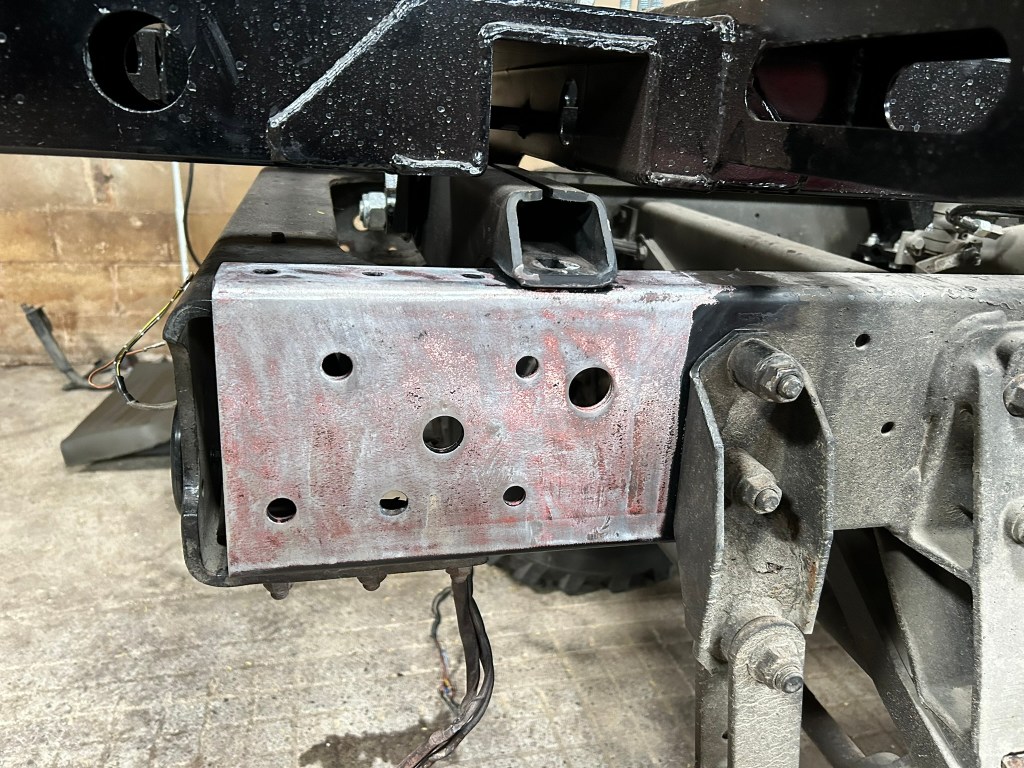

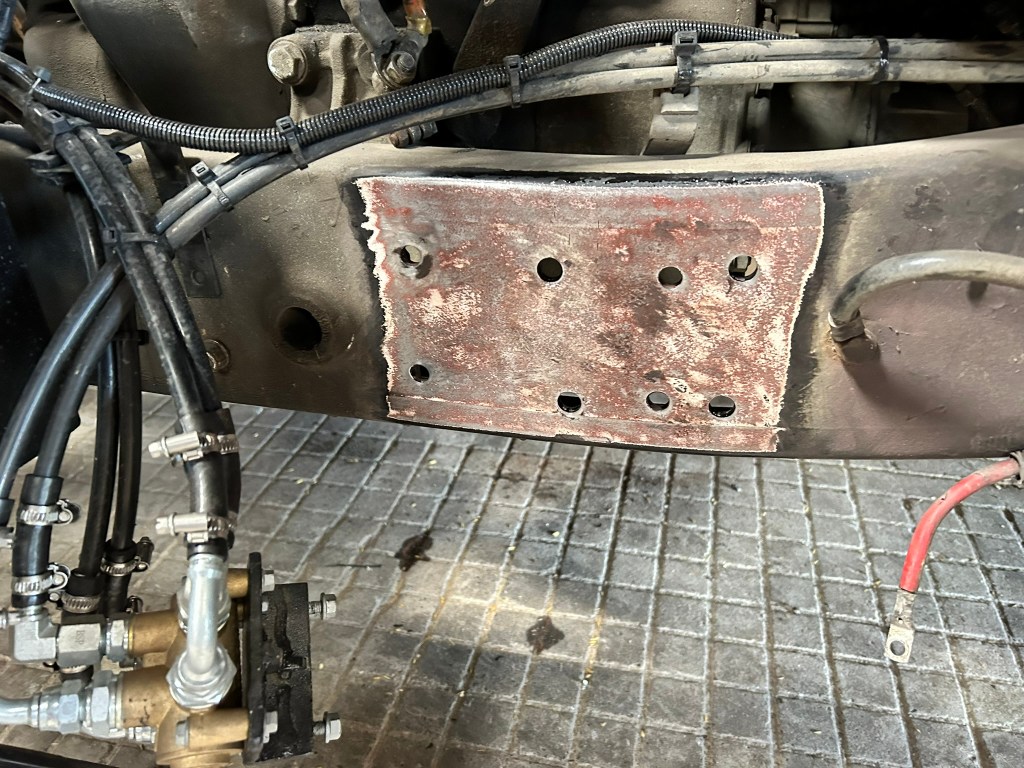

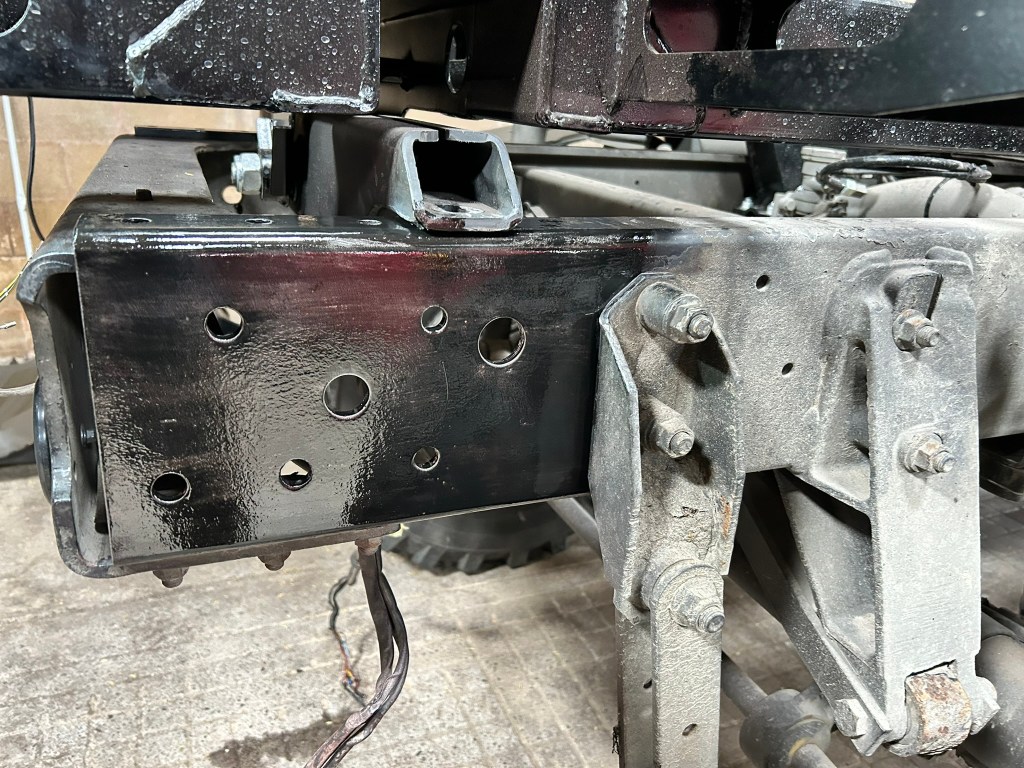

The battery box was in a terrible state

And there were various other elements that needed work if our UniMog was going to be pristine

Everything was removed, cleaned up and taken to a fabricator and powder coater for repair. Car loads of parts were taxi´d back and forwards

And by the time we had finished, everything was looking as good as new

A new exhaust pipe had been fabricated

And the whole thing painted with heat resistant paint

We sourced a repair panel for the mud guard and had it welded on

Then both mud guards were prepared ready for painting and you could hardly tell a repair had been done…

We found a few small bits of rust on the chassis

Which were sanded down and treated

Then painted with heat-resistant rust-proof paint

Underneath may have been looking good but there was still a lot of work to do on the cab itself

There were a few bits of rust in the floor as well as some holes cut by the fire service for their equipment to run through

It wasn´t bad at all for its age but it needed treating.

Each spot was sanded down then the whole floor covered in newpaper

Before treating the rust and re-painting

By the time we´d finished it was as good as new

We also counted seventeen holes in the roof from the blue lights, sirens and other equipment. Each one was meticulously rubbed down

Then we had small, steel blanks made and bonded them in to make a waterproof seal

Everything was then painted over

Until the roof, as well as the floor, looked perfect

With all the trims and mats out it was a good time to sound proof the entire cab. This was a long and fiddly job that took days

James then set about installing the new rear tail lights. We had bought new ones from a lighting place a few weeks before and the wiring was incredibly complex

But by the times James had sorted it all out they were looking very crisp

And last but not least, we collected up the old and dirty lining from the cab

Took it to an upholsterer

And had it re-lined in alcantara fabric and leather

As well as spending two days scrubbing the foot mats until they gleamed

The re-upholstered lining would not go back in until after the cab had been painted but even so our 23 year old UniMog was starting to look a little different

I had even spent an entire day carefully removing the commercial reflective strips off the doors which in itself made a surprisingly big difference

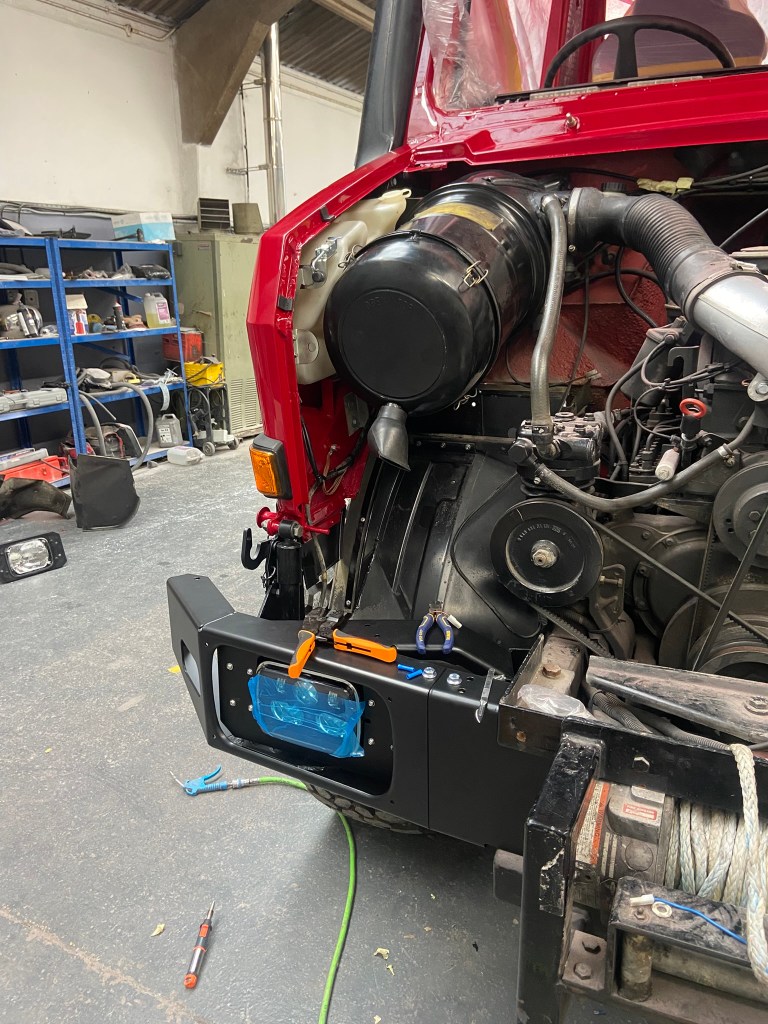

Meanwhile Pegasus were snowed under with work and were desperately trying to find some space – both in their workshop and their schedules – to fit us in. Finally, three weeks before the box was due to arrive in Southampton, we had the call from Jonathan telling us to come in. The timing seemed perfect.

The new driver’s seat was dropped in and cabled up, the old bumper and headlights temporarily fitted back on and the batteries recharged. We were ready for our first ever drive in our UniMog on a public road

It was an exciting day, seeing our new addition making its way down the road, I couldn´t help but think it looked very cute!

We arrived at the workshop to great interest from the Pegasus team. Sitting there, taking up most of the space in their unit, it was clear that painting this huge thing was going to be a massive undertaking.

Tape measures are all well and good but our first priority was to make sure that the UniMog really would fit into the painting oven

James slowly and carefully drove towards it, watched by eagle-eyes all round. The cab was just too high to get under the door but we had been expecting that. The tyres were slowly let down, millimeter by millimeter until finally there was enough clearance. We were good to go!

But actually painting a vehicle is just the very, very last step in a very, very long preparation process. The UniMog was slowly backed out of the oven into the workshop and the real work started…

First the doors came off and everything was removed from them

Then the mirrors, windscreen wipers, stalks, indicators, steps, grill, bonnet, bumper, headlights and a hundred other parts were removed

Even the windscreen had to be taken out.

The air filter housing and windscreen washer bottle had to be removed in order for the new side wing to be welded in place

And finally the whole cab was rubbed down and fillered ready for painting

Our UniMog was looking very sorry for itself yet again

But we were making progress. It was now time to start preparing all the smaller bits and pieces. Firstly the doors were cleaned, rubbed down and fillered

The grill and bonnet were also prepared ready for painting

And we even removed parts of the dashboard to be repainted

Bit by bit each part was taken into the painting oven and sprayed, including the repaired mud guards

Meanwhile James and I carried on with the work we had been doing at the farm. A bit more cleaning of the chassis and few more bits and pieces of rust treated. Everything that came off had to be cleaned and degreased and any overspray from an old paint-job by the fire service was scraped away.

And whilst all this was going on, the old, rusty wing was removed and the new wing was welded in place

One of our most important jobs during this period was to choose the colour of the paint. We wanted it red, how hard could it be? By the time Jonathan had presented us with over two hundred shades of red we discovered the answer to that – very!

We knew we wanted to get away from the orangey red of the fire engine but finding the right shade of deeper, richer red was a challenge. It seemed that every colour card changed shade in front of our eyes depending on what light it was in and what other colours it was next to. The job seemed impossible.

And even when we chose the right colour, trying to match the shade properly in the paint system took at least another week.

But, some two and a half weeks after we arrived, we were finally ready to drive the UniMog into the painting oven for real this time.

No-one at Pegasus wanted to risk driving it themselves so James yet again took on the job no-one else wanted and slow and carefully drove towards the doors. It took nearly half an hour to manoeuvre it in

But eventually we were ready

The doors were closed, masking tape and plastic sheets were carefully taped on and then it began

First the final rub down and clean

Then the bare metal was treated and the primer went on

At every step I hoped we would see red appearing but I had to contain my impatience.

Eventually I saw Jonathan heading back into the oven with bottles full of red paint. I was so excited. But my excitement had to be contained yet again – he walked out looking worried, in and out he went, holding sample cards, calling his colleague in, shaking their heads together, then phone calls were made.

Eventually Jonathan came up to me with the news – for the first time ever in his entire career the paint company had sent the wrong colour!

I was not at all surprised – with the way our luck had been going it was inevitable. The box was due to land in Southampton in one week and we still had no paint on the UniMog.

It was another two days before the painting could be started but finally everything was in place and off we went

It was looking very hopeful in there…

But we were to face another problem – somehow silicon had got onto the outside of the cab and the paint had simply slid and bubbled off. Jonathan was devastated, this was not the quality work he normally provides and he had wanted this special project to be the best. It took another two days of re-spraying, polishing and touching up before he was happy.

Because of the UniMog´s height he couldn´t paint the roof in the oven. So by the time it came out it was still only three quarters done – the roof would have to be finished the next day when the rest of it had dried.

But the parts that were done were looking amazing

It´s unusual for Jonathan to paint a vehicle outside of the oven and the whole workshop had to be covered in plastic to protect it from the overspray. And that included the Unimog

We were still trying to get the work underneath finished at the same time

But we were now asked to vacate the premises and let Jonathan do his thing with no distractions. By the time we got back everything was very red!

As the paint on the roof was drying, James started the rebuild, firstly getting everything under the bonnet back in

Then all the hundreds of other bits fixed back on

Slowly but surely it was all coming together and by the time the plastic sheeting came off we had big smiles on our faces

Finally the internal upholstery, leather door cards and the new air seats were installed

It had taken nearly four weeks – a lot longer than anyone expected – but we were in luck because, absolutely as expected, our ship had been delayed coming across the Atlantic. Rather than 22nd October, it was now due in overnight on 25th/26th. Our UK shipping agent advised that we had 5 days to collect the box after it had been unloaded so we had booked our slot for Tuesday 30th.

James worked tirelessly on the rebuild for seven days without a break and miraculously we were done on the Monday night before we were due to be at the port.

We sat back and admired our handy work….not bad at all

It was becoming apparent that our UniMog was going to be even more special than we had hoped…

9 responses to “The Start of the Build”

Wow another top notch vehicle transformation, you are both truly blessed with the skill set of the people around you and your own skills .

LikeLike

It’s all James! I’m his assistant but you know the quality of his workmanship, second to none…and yes, we have some great people around us, we couldn’t have done this without Jonathan and his team

LikeLike

This the fun part?

Good thing you guys are still young!

LikeLike

This is definitely not the fun part! Roll on completion of the build and restarting our travels 🤞🤞

LikeLike

Great to read the story in detail and can’t wait to see the finished product! Well done you guys!

LikeLike

We’re getting there…slowly!

LikeLike

can’t wait to see finished product!!!!!!

LikeLike

Red is the only colour for an overland vehicle ! (But I am very biased !)

Looking good and it will be a treat not to have any deadlines to work to when you get on the road.

Going up to the bigger tools for the bigger meccano style of the mog no longer living with a 10mm & 13 mm spanner in each pocket.

‘It will be worth it in the long run’ should be your moto for the next part of the build!

looking forward to seeing the yet unnamed truck on the road !

LikeLike

Thanks Gary, looking forward to being back on the road more than anything!

The fit-out is coming along well now and even I have to admit it’s looking pretty special – we get a few looks driving down along already 😉

LikeLike