We had been working on the UniMog for over two months and it was looking pretty special

James had worked tirelessly for a solid week refitting all the bits and pieces to it after the painting had been finished. He had also decked the subframe out in plywood in order to sit the habitation box on it for transit up to South Cave Tractors in Hull where it would be properly fitted

The night before we were due to collect the box, James finally drove our beautiful Fire Truck from the workshop to my Mum’s place and when he appeared at the end of the road, flashing his lights in greeting, my heart was in my mouth

We were ready to go

The journey down to Southampton was fun, our first drive together in the UniMog

But tensions were high. This box had taken three months to build and ship and had cost us almost as much as the UniMog itself. But, being made from fibreglass and insulating foam, it was going to be easily damaged if we weren’t very careful.

We had already had one scare. Three days earlier, the shipping container had been transported from the port to the warehouse where the box was to be unloaded. The company responsible for the unloading had called our shipping agent to say that the box had shifted inside the container enroute and might have been damaged. I took the call from the agent and was gutted. The company wanted our permission to unload despite the risk of further damage and we had little choice but to agree. Fortunately, the manufacturer – Off Grid Customs – had packed and protected the box so well that it was still in perfect condition and after a couple of hours of pacing up and down waiting for the phone to ring we finally got the good news that the box was out of the container and all was well.

We just hoped things stayed that way. Our plan was to have the box lifted onto the back of the UniMog and strap it down with three ratchet straps. The box itself weighed only 560kg and we hoped that it was light enough not to tip too much as we drove to Hull. It was a leap of faith – everyone we spoke to told us not to do it, advising us to have it transported to Hull still in the shipping container but the costs of that were too high and James was confident. Well, as confident as it gets when you’re talking about risking your life’s savings down the motorway!

We arrived at the warehouse and the staff were intrigued as to what was under all the wrapping. When they saw the UniMog and we explained it was a habitation box for an overland expedition truck it seemed that we had given them about the most exciting explanation they could have thought up.

What followed was the most stressful two hours of our lives – or at least since we had had to drag Henry back up from the bottom of a mountain.

First the box had to be very carefully loaded onto the forklift. This was a delicate job as the forks could easily pierce the fibreglass if the driver wasn’t millimeter accurate. James kept a close eye on proceedings

But once it was on the forks the stress levels just kept getting higher. The driver lifted the box so that it was level with the UniMog – he went as slowly as he could whilst the box wobbled from side to side making me hold my breath and want to be anywhere else but here. James reversed the UniMog towards the box and slowly and carefully the driver moved forwards and lowered the box down

The full video of this was over six minutes long, the driver easing the box down millimeter by millimeter then moving it backwards and forwards, side to side to make sure it was exactly centred where it needed to be. If he was slightly out, the journey to Hull would almost certainly end in disaster.

When the forklift was finally taken away and the box sat on the UniMog in all its glory we all breathed a sigh of relief – not least the forklift driver

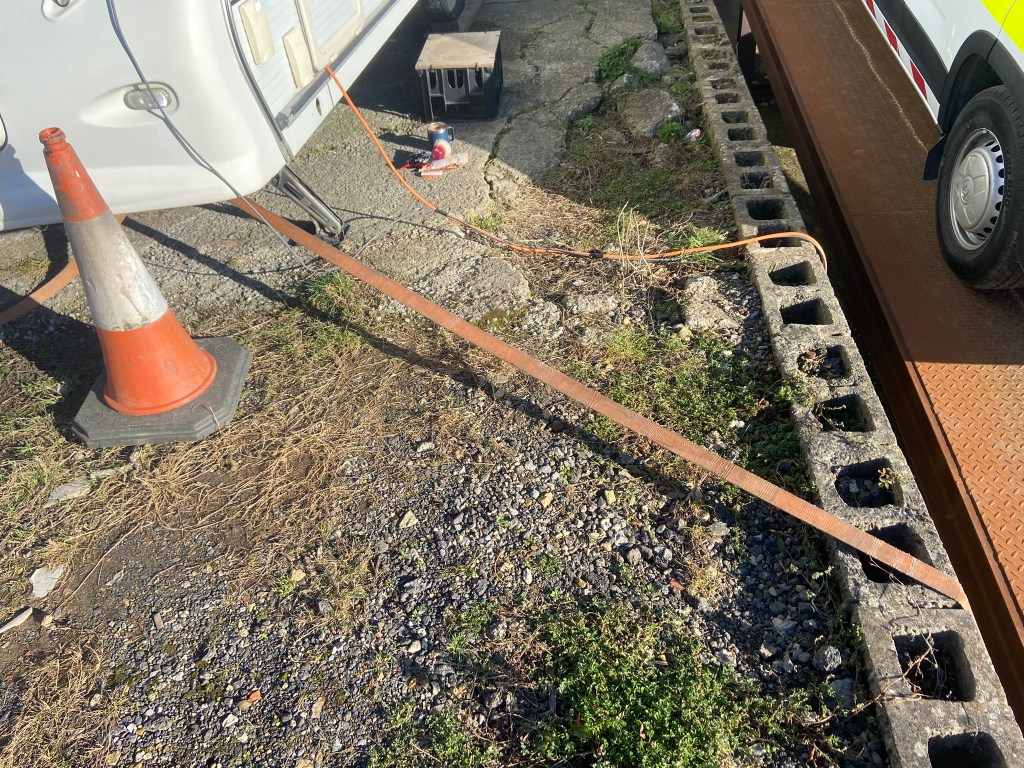

James threw the ratchet straps over it and spent half an hour or more painstakingly tying it all down, protecting the top of the box with foam and making sure there was enough tension to hold it but not so much to crush it

Finally we were ready to go, with our hearts in our mouths

As we exited the gate and went round the small roundabout onto the main road the sub frame leaned over to the side as it is designed to do and the box leaned over with it. I watched out of the window, barely able to look, but as we straightened up the box straightened with us and comfortably settled back down

We looked at each other with tentative smiles – we had a long way to go but it had passed the first test.

We stopped at a fuel station to refill for the long journey back and realised just how big Henry’s big brother is!

We were only going as far as my Mum’s house today, it was too far to try and make it all the way to Hull. It took two and a half tension-filled hours but we only had one minor issue along the way – just as we got onto the motorway the wrapping around the box started to unwind and was flapping about in long fingers across the carriageway. We got off at the next junction and pulled over in a layby whilst James cut the loose bits off and secured the rest of it. We detoured along A roads for a while until we were sure it was all ok then rejoined the motorway and got to Mum’s with no further problems.

Seeing the UniMog sitting there with his box balanced on his back was a sight we had been waiting to see for a long time, it seemed hardly real

Before we went to Hull there was one more task we needed to get done. The windows and doors had arrived months earlier from the Netherlands and we wanted to fit them to the box before it went anywhere else. They were all at Pegasus where the UniMog had been painted so James drove up there the next morning intending to spend a couple of days installing them all

When we first arrived back in the UK we had checked the windows and doors over and found that the two hatches for the garage area had been made the wrong size – they were to fit a 60mm thick box not our 80mm thick box. The supplier had admitted their mistake and sent new ones to us. However, when James arrived at Pegasus the next day and started work he found to his dismay that all the windows were the wrong size as well. It had not been obvious by measuring them without the box there, the mistake only became apparent when he tried to fit them.

Many, many phone calls later, and with assistance from the UK agent for the Dutch supplier, they finally agreed that they had sent the wrong things and set about re-making new ones. But it would take days to get them built and shipped over, maybe even a couple of weeks. We had a start date with Adaptvan we had to meet, we couldn’t wait any longer.

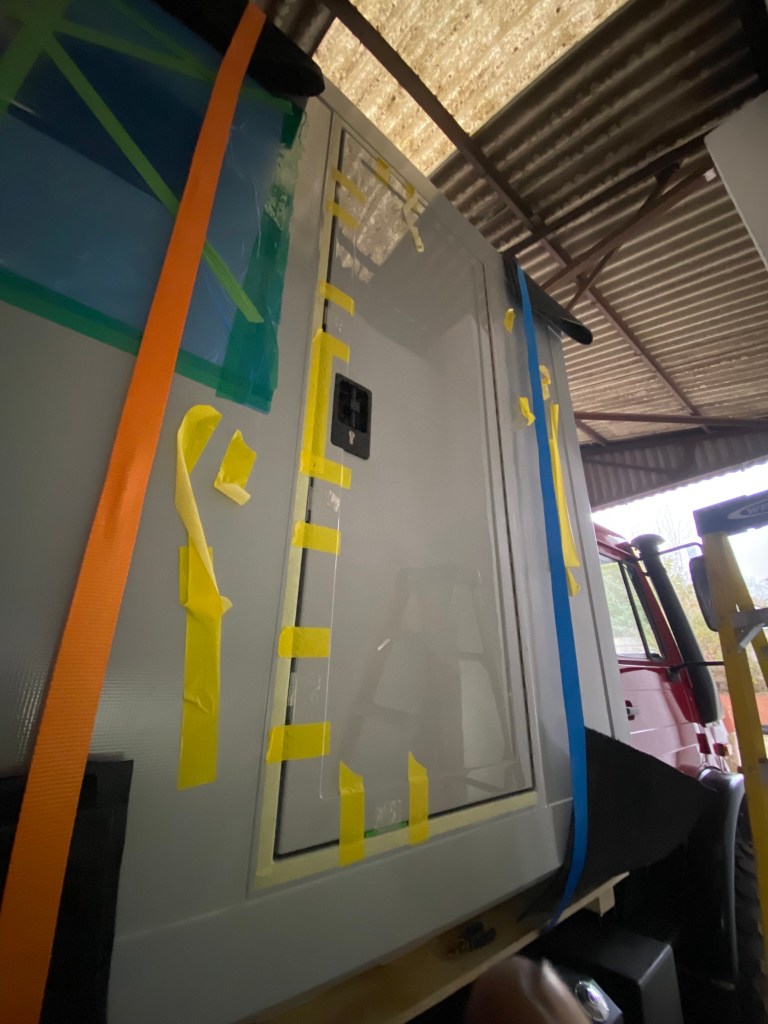

The only things that fitted our box were the main entrance door and the roof light. So James single-handedly installed those with only instructions from the supplier’s website and a bit of help from their head engineer over the phone

How does he do these things? He had to lift that large, heavy door in and hold it in place on his own whilst he fixed it, all whilst balancing half way up a ladder – I often think he must be superhuman! He’s certainly determined.

Two days later we were ready to take the UniMog to Hull and get South Cave Tractors to fit the box permanently onto the sub frame. James drove the UniMog and I followed in the car – so far, at this point, I had not driven the UniMog on public roads as I needed rather a lot more practice with the gear box before I was safe behind that particular wheel.

We left our beautiful Fire Truck with them knowing he was in good hands – but I still extracted promises from them all before we left that they wouldn’t drop the box!

They sent us photos of it being lifted off the plywood

And being safely stored in their workshop

It was all looking good

But two days later we had a phone call – there was a problem. As part of their work to design and build the sub frame, South Cave Tractors had advised Off-Grid Customs on the requirement for two cut-outs in the floor of the box where the shock absorbers would need to rise up when the vehicle articulated. Off-Grid Customs had made these cut-outs exactly as requested, complete with aluminium pockets to line the holes. The problem was that South Cave Tractors had got it wrong – the pockets were too small and the box would not fit on the sub frame.

We went into a tailspin, but only for a couple of minutes. The guys at South Cave Tractors took full responsibility and offered to re-cut larger holes and make new aluminium pockets all at their own cost. We were able to breath again but this would mean yet more delays.

They set about the work, first testing the maximum lean on the sub frame with heavy steel blocks

They then cut the box, fabricated the new pockets and put it all back together again

Before carefully lowering the box back onto the sub frame and testing it out. This time it all looked good

Another few days of bonding, bolting and sealing and finally we had the call – our UniMog was ready to collect. It was a red-letter day, things were coming together. Our new overland truck was now all in one piece, undamaged in transit and ready for the final stage.

Our lives were about to change again at last – three months after we had first arrived back in the UK we were leaving the warmth and comfort of my Mum’s house in Warwickshire and taking our UniMog and all our possessions up to the wilds of Durham to start work with the team at Adaptvan fitting out our new living quarters. We expected this to take another three months or so and were champing at the bit to get going.

Whilst we had been there, we had filled my Mum’s house up with UniMog parts and she was having difficulty moving around!

So we packed as much as we possibly could into the car and drove to South Cave Tractors.

Our UniMog was looking fabulous

Everything from the car was transferred into the UniMog box and I stood in the yard watching as James slowly drove out of the gates heading north

I drove back to Mum’s, loaded another pile of things into the car and the next morning hugged my Mum goodbye and followed him up there….

Our arrangement with Lewis at Adaptvan was that we would fit the UniMog out in his large workshop, use his tools and have 2 hours of his time each day as consultancy. We would also live on-site during the fit-out, having borrowed a friend’s caravan and had it installed a few metres from where we would be working. It was an ideal set-up that worked extremely well for all of us

But there were downsides to our plan, mostly due to the time of year that we were doing the work – Durham is less than two hours from the Scottish border and that far up north it gets cold…very cold. The farm where Adaptvan are based is also right on the coast on the highest hill in the area so when Durham itself was cold the farm was bitter

When we first arrived it was below zero and we even had snow, not ideal for two people used to the African climate

The workshop was very cold all the time – there were two large fan heaters taking the edge of it but only if you stood right next to them.

The caravan we were living in was lovely. It was spacious and comfortable and had everything we needed – the farm provided us with water, power and even broadband and we had a shower and chemical toilet onboard

Lewis and his wife, Clara, were kind enough to let us use their washing machine, put our rubbish in their wheely bins and even invited me to use their shower on the days I needed to wash my hair.

We had already purchased all our kitchen equipment ready to furnish the UniMog and took the opportunity of getting used to the new air fryer, induction hobs, kettle, toaster, sandwich make and saucepans

We were rocking and rolling!

But there are limits to what a caravan can achieve in sub-zero temperatures. They are designed with summer holidays in mind therefore heat and insulation are not top of the priority list. So everyday we went from a freezing cold workshop to a freezing cold caravan, we just could not get warm. It was relentless and a huge shock to our systems.

James was not quite so bad as he was keeping warm working hard on the fit-out but my role was as his assistant – tasked with shopping, researching, planning and looking after him by keeping him fed and watered. I spent much of my time sitting in the workshop on the computer shivering and gradually my core temperature was dropping. After the first two weeks I started to get ill. Fortunately around this time our new windows arrived at Pegasus so we went back down south to collect them and stayed with my Mum for the week-end. I got my bones warm again and by the time we arrived back in Durham the weather had improved a lot.

It was not to last. We spent ten days over Christmas back down south with family and when we returned it was to arctic conditions

Our water tanks froze and for five days we had no water

I spent my time walking backwards and forwards between the caravan and the workshop kitchen filling pans, kettles and anything else I could get my hands on just so that we could wash, brush our teeth, do the washing up and have something to drink. For five days a shower was out of the question!

And a couple of weeks later Storm Eowyn hit us, apparently the UK’s most powerful windstorm in over a decade. Being on the coast and on top of a hill, that day was both awe-inspiring and terrifying. The caravan was rocking so hard I had to hold on to the worktop to try and stay upright. With gusts up to 100mph it was decided early on that work on the UniMog had to stop for a while whilst the caravan was strapped down to stop it being blown over

But despite everything that the weather threw at us, the convenience of living on site meant that we could maximise our working time and James regularly put in twelve hour days, six days a week. He even had his Friday-night beer in the workshop!

I brought him breakfast and lunch each day so that he could keep going and he often didn’t stop in the evenings until he was practically on his knees. On Sundays we tried to do something fun but all too often they were just spent sleeping. And for the last four weeks we didn’t even take Sundays off at all.

We were on a mission – not only did we only have ten weeks to do a fit-out that should take sixteen, we were also absolutely desperate to start travelling again.

With all this work we both became exhausted and of course that’s when accidents start to happen. At one point the top of the composting toilet snapped down onto James’ thumb and it did so much damage that he had to stop for a moment to clear his head. Later on in the day I caught him drilling into his thumb nail to try to release the pressure under it – I felt felt sick when I realised what he was doing but he just grinned and said it was ‘construction site surgery’!

Over the next few days it went black and eventually peeled off altogether

We lost count of how many times heads were bumped

As well as hands cut, toes stubbed, fingers bent, arms scratched and bruised, backs pulled and muscles torn.

However, we could not entirely blame the UniMog for the strange swelling on James’ leg that just wouldn’t heal. At first we thought it was an ulcer forming as he was on his feet all day every day. But eventually, after many weeks, it started to dry up and we were amazed to find that this particular injury can only have been picked up before we left Africa. There’s only one thing that leaves bite marks like that…

In the end it took fourteen weeks to complete the work and we moved mountains in that time. Lewis said he couldn’t believe the rate at which James was getting things done and often expressed concern for his health as he worked himself into the ground. But he was relentless and determined, there was nothing in our lives apart from the UniMog from the middle of November to the middle of March.

There will be a separate post with a photo-montage of all the work we did showing how it all slowly but surely came together to create a masterpiece…watch this space

6 responses to “The Living Quarters”

what one thing bit him?

LikeLike

Looks like a snake bite…it still hasn’t healed properly

LikeLike

it also looked like a snake bite to me, but I couldn’t understand why it went unnoticed before this…ouch!

LikeLiked by 1 person

To be honest, James has so many strange things happen to his body he just stops worrying about it! His legs are never in a good state with lumps and bumps and swellings – the consequences of being a builder all his life. It generally takes him a while to realise that something isn’t normal – it took him three days and a doctor to realise what he thought was gout was actually cellulitis, he thought he was just in shock from the accident in Swaziland but a week later realised it was actually a tick infection…the list goes on! I’m not at all surprised he thought a snake bite was just his veins playing up 😬

LikeLike

He follows his Dad for hard working. That’s how we were raised. Hate to see my little brother hurt though

LikeLike

He’s a hard worker, that’s for sure! Don’t worry about the bumps and bangs though, all part of the usual course of events for James as you know 😊

LikeLike