Back in September 2023, when Henry’s gearbox needed replacing in Namibia, I wrote a post entitled ‘The Perils of Owning a Landrover’. It therefore seemed appropriate, and only fair to our two boys, to name this one accordingly.

We had a lot of bad luck in the initial stages of the UniMog’s build but managed to work through it all successfully. The fit-out in Durham was hard work in difficult living conditions but went very smoothly.

Since then, however, BigMog has been trying his best to rival Henry for the crown of ‘Most Problematic Vehicle Owned by Jen and James’ and I can tell you that there is stiff competition all round for that particular prize!

It had become clear as we drove the winding and narrow roads of the Scottish Highlands, that all was not well with either BigMog’s clutch or gearbox – or possibly both. James had spoken to the UniMog Hospital in Hull – South Cave Tractors – more than once about the symptoms and they had some ideas about what might be the cause. But of course they would need to see him and road test him before they could be sure.

To put what we were facing into some perspective, changing Henry’s complete clutch and gearbox, including shipping one from the UK and the other from South Africa – plus the customs duties involved – cost us a grand total of £2,500. To change a clutch in a UniMog would cost somewhere between £4,000-£5,000 and to change a gearbox would be £15,000 for the gearbox plus around £6,000 in labour. So we could be looking at up to £25,000 to do both on BigMog and that would be without needing to pay for shipping or duties.

I re-read my ‘Perils of Owning a Landrover’ post before writing this to remind myself of the pains we went through and in it I had said that our travelling budget was ‘in freefall’. At that point Henry had cost us just over £5,000 in three months between the clutch, gearbox, new tyres, brake pads and springs, mud guards, anti-roll bar hanger, crown wheel and pinion, rear differential, bearings and various gaskets, clips and filters. A lot had gone wrong in a short time and it was no wonder we were feeling less than confident in him for a while. But in comparison to what we were now facing with the UniMog it was small beer.

Now, not only were we having gearbox problems but the new fuel tank we had had fitted by South Cave Tractors was also playing up. It kept pressurising and blowing large amounts of fuel out of the top. Or we would be driving along with the tank over half full when a vacuum would form inside which stopped the fuel from being able to come out and the engine would cut out in the middle of the road. We made sure we always had fuel in the main tank so that we could quickly switch over to get going again but it was less than ideal.

Plus the small inverter, the one that contained the brains of our electrical system, had developed a fault and our control panel could no longer speak to it.

So, all in all, there were a few issues to deal with. BigMog was booked in at South Cave Tractors for diagnosis on 14th July, it was the soonest they could fit him in. James dropped me at Carlisle station on 28th June. So we had two weeks in between and a whole lot to get done.

James drove straight to Lewis’s place in Durham, where we had done the fit-out. Lewis was happy to have him back and gave him space in the workshop for as long as he needed

The list of things to do was long. Some of it was stuff that we had run out of time to do before Scotland, the rest of it were things we had wanted to think about and test out on our pilot run before making decisions.

The first job was to fix the inverter. It turned out to be in need of a software update which Lewis did for us online – easy fix, big relief.

Then James started on the winch. We had decided against putting a new one on the back so needed to fix up the existing one on the front. The plan was to take it apart, clean it up, get the bracket powder coated and replace the solenoid so that it actually worked

It was a time consuming job but worth it to give us options if we ever got stuck.

James then mounted our two fans on brackets above the bed

He also had to fix the indicator stick that had come loose which meant making making a tool to remove the steering wheel

The weather strips on the doors had turned out not to be very weather proof so he replaced those, requiring a complete strip of the doors. He had hoped to replace the door lock and ignition set that we had ordered from South Cave Tractors whilst the doors were stripped but Mercedes were having trouble getting the spare key cut properly so it hadn’t arrived yet.

One of the biggest jobs was to build a pump-system in a case for us to use to fill up our water tank from a river or similar – if we were somewhere remote without taps available. This took him over a day just on its own but the result was very impressive

Next up was to mount the new sand ladders on the back

And fitting the toilet roll holder, bottle holder and bin in the wet room – to keep us a bit tidier

There was a leak on the wet-loop system from the engine to the boiler which he fixed. And he changed the clutch master cylinder as some people suggested that might be the cause of the gearbox problem (it wasn’t but it was a good job to get done anyway).

And finally he changed two ball joints and had the tracking done

There was still more to do but by now his time was up and he was exhausted again. So he drove BigMog to the hospital in Hull where I picked him up and drove him back to Mum’s whilst he snored quietly in the passenger seat. We had been apart for two weeks, the second longest we had ever been away from each other.

South Cave Tractors had been endlessly upbeat about the gearbox problems. UniMog gearboxes don’t go wrong and neither do their clutches, not at such low mileage as BigMog had. It will be something simple they said. The most likely cause, they assured us, would be the bushes and/or bearings in the gear selector which is a simple and inexpensive fix.

We believed them, they are good guys and they know their stuff. So come Monday morning when they test-drove him and declared their assessment to be most likely right, we were happy and started excitedly planning the start of our next adventure. At last, we were about to set off back into the big wide world.

A day passed, then another, then another. We kept ringing them but, whilst they were friendly and chatty with us, such a small job was clearly not their priority. The parts were ordered and eventually fitted but it took another day and a half for them to clear the other vehicles out of the way to get BigMog out of the workshop and road tested again. By now it was Thursday afternoon – four days had been wasted and we were anxious to get him back home and get ready for departure.

Evenutally I had a call from them and from the tone of the voice on the other end I could tell straight away that it was not good news. The gearbox was a little better but still clunky and difficult. The small job had not fixed the problem. The next step, they said, was to take the gearbox out and open it up to see what, if anything, was wrong inside. Total cost of the labour to do this – £6,000. And that was without even fixing any problems they found.

We went into freefall. James rang a gearbox specialist and was given some frightening figures for repair work and that was just for a minor refurb on the basis that the gearbox was already out of the vehicle and couriered to them.

South Cave were concerned at this turn of events and suggested that we went back to them to test drive BigMog for ourselves and chat to their lead technician to agree a plan of action. We waited for the lead technician to call. We waited until Monday afternoon of the following week before I finally managed to make enough of a nuisance of myself that someone went to go and find him and put him on the phone.

We agreed to go up the next day and arrived on their doorstep at 7:45am, fifteen minutes before they opened. Jo, the lead technician, talked us through everything. He said that everyone in the organisation had done a test drive and they had all discussed their findings. All but one thought it was possible that this is just what UniMog gearboxes are like, one person said he could definitely detect a problem. They all agreed that with the gearbox having been fine three months ago and now being difficult that was a bad sign.

James took BigMog out for a drive, with Jo in the passenger seat. He came back saying that it was definitely better than it had been but still not how it used to be before Scotland. He then drove out in another UniMog with the same gearbox type to try it as a comparison. He said it was better in some ways and worse in others.

We were at South Cave Tractors for over four hours discussing options. They really didn’t want to spend £6,000 of our money only to find out there was nothing wrong, or at least nothing we needed to have worried about. But equally they didn’t want to send us off on our one-way trip to the middle of nowhere only to have us breakdown with no support.

It was an impossible situation. In the end we all agreed that support would be relatively easily available in Europe and we would be around Europe for a few months before disappearing into more far-flung reaches. So we bit the bullet and decided to take BigMog away with us and carry on as if everything was ok.

James drove him to Redditch, back to our nephew’s workshop where he had been painted. There was space there to finish everything off that was still left to do. We were both thrilled and our spirits were high, the re-starting of our adventures was within reach at last.

An hour later, the clutch gave out and BigMog was crawling along the motorway at 30mph until James limped him into a service station. Whilst underneath with all his tools, he discovered an oil leak from the gearbox and found that the fuel tank still had not been fixed despite South Cave having assured us that it was all sorted.

When would this ever end? If James had lost confidence in Henry after his spate of problems back in 2023, so I had completely lost confidence in BigMog now.

Strangely, given how bad things appeared, James was not willing to consign BigMog to the naughty step just yet. Which was probably a good thing as we really didn’t have one big enough!

And even more strangely, that evening was the low point, things got very much better very much more quickly than we could have hoped.

Firstly, once James had tinkered with the clutch, he had no more problems all the way to Redditch. And we have not had any further problems since. Our best guess is that this had nothing to do with the original gearbox problem and was more likely related to the new master cylinder which may have got an airlock in it.

The oil leak was quickly fixed by James and a few tools. And South Cave Tractors decided that the fuel tank problem was down to a faulty sender. They ordered a new one for us and James drove BigMog back up to Hull a week later, installed it himself and the problem vanished

Meanwhile, after three days in Redditch, we had a new wifi dish installed

Our axe and shovel were properly secured onto the roof rack

The last few bits were powder coated and reinstalled

A new wing mirror was fitted where there should have been one before

And the correct spare key was finally delivered by Mercedes so the new lock set could be installed

A new-style, lightweight fire extinguisher was mounted

And finally, James did a full service, changing all the oils

James had lived in the workshop for three nights and I joined him for one of them. It was not our most salubrious campsite!

But eventually the three of us were back at my Mum’s and the last few finishing touches were put together

A new custom-built tool box had arrived and was fitted

Along with a mirror for the wet room door

A clever locking system had been devised by James for the steps on the back

And everything was cleaned to within an inch of its life.

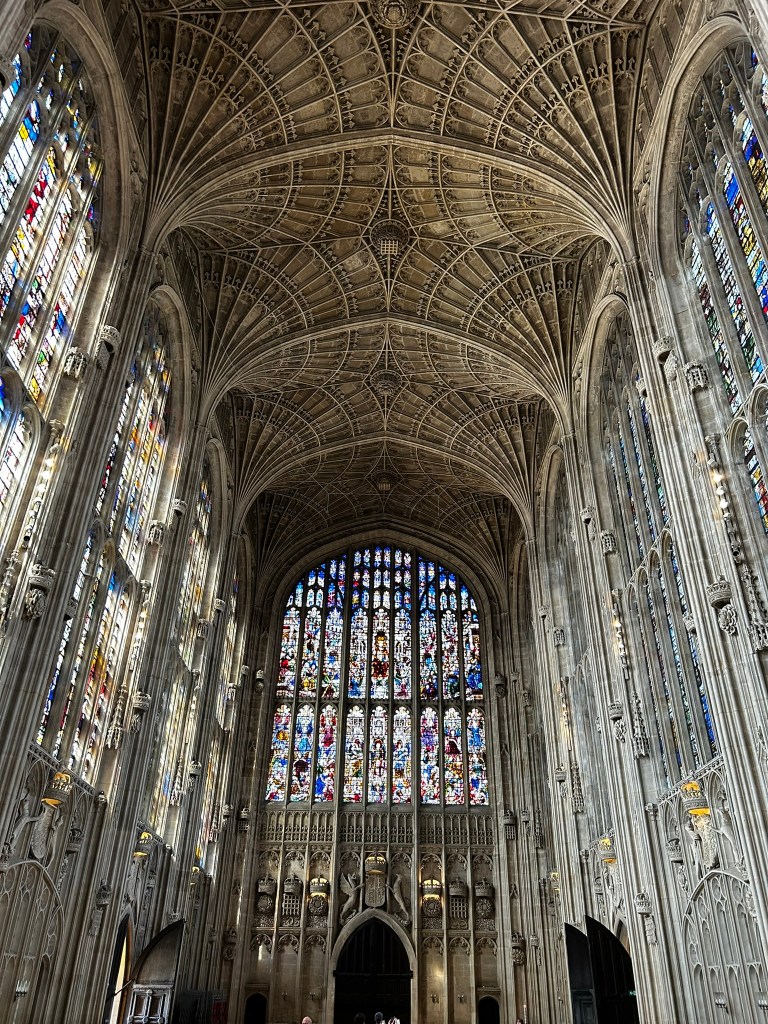

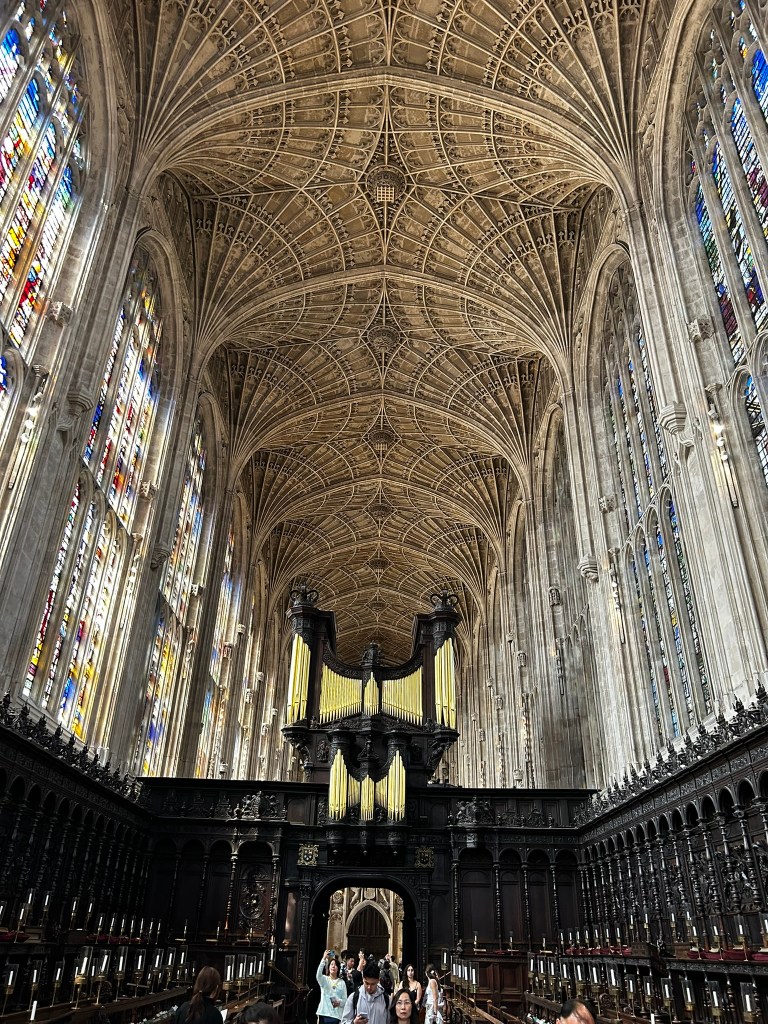

We had been back from Scotland for five weeks now and to celebrate having made such good progress we decided to go to Cambridge for my birthday and pop in to see my old college

I hadn’t been back to the University for over 25 years but the place hadn’t changed one bit

A fitting tribute to England before we left.

BigMog was finally ready, our ferry tickets were booked and we were beaming with excitement and more than a little relief.

There was just one thing left to do. BigMog was a stunner, there was no denying that, but he was looking a little bare. What he needed now was some artwork on the sides to bring him to life.

We had spent months trying to design something appropriate. With our love of Africa and my love of lions, what seemed most appropriate was to find a big mog for BigMog

And so we set off from my Mum’s place, waving a tearful farewell as we left the village behind once more

Our first stop was Gloucester where the magic happened

If BigMog had been a head-turner before it was nothing compared to the looks we were getting as we trundled down the road now

And trundle we did. From Gloucester to Oxford, from Oxford to Epping and from Epping to Dover – it takes a long time to get anywhere in a UniMog! But the big day had arrived – it was Friday 15th August 2025, a day to rival 6th September 2021.

We loaded BigMog onto a ferry and sailed him away from the UK, almost certainly forever. As Henry will never return to UK roads, neither will BigMog. The three of us were sailing away into the winds, breathing in the fresh air and freedom that can only be found in a life on the road, the life of nomads. Sidetracked once again…

2 responses to “The Perils of Owning a UniMog”

Safe travels!

LikeLike

Thanks Chris, hope all is well

LikeLike